Precision in Motion:

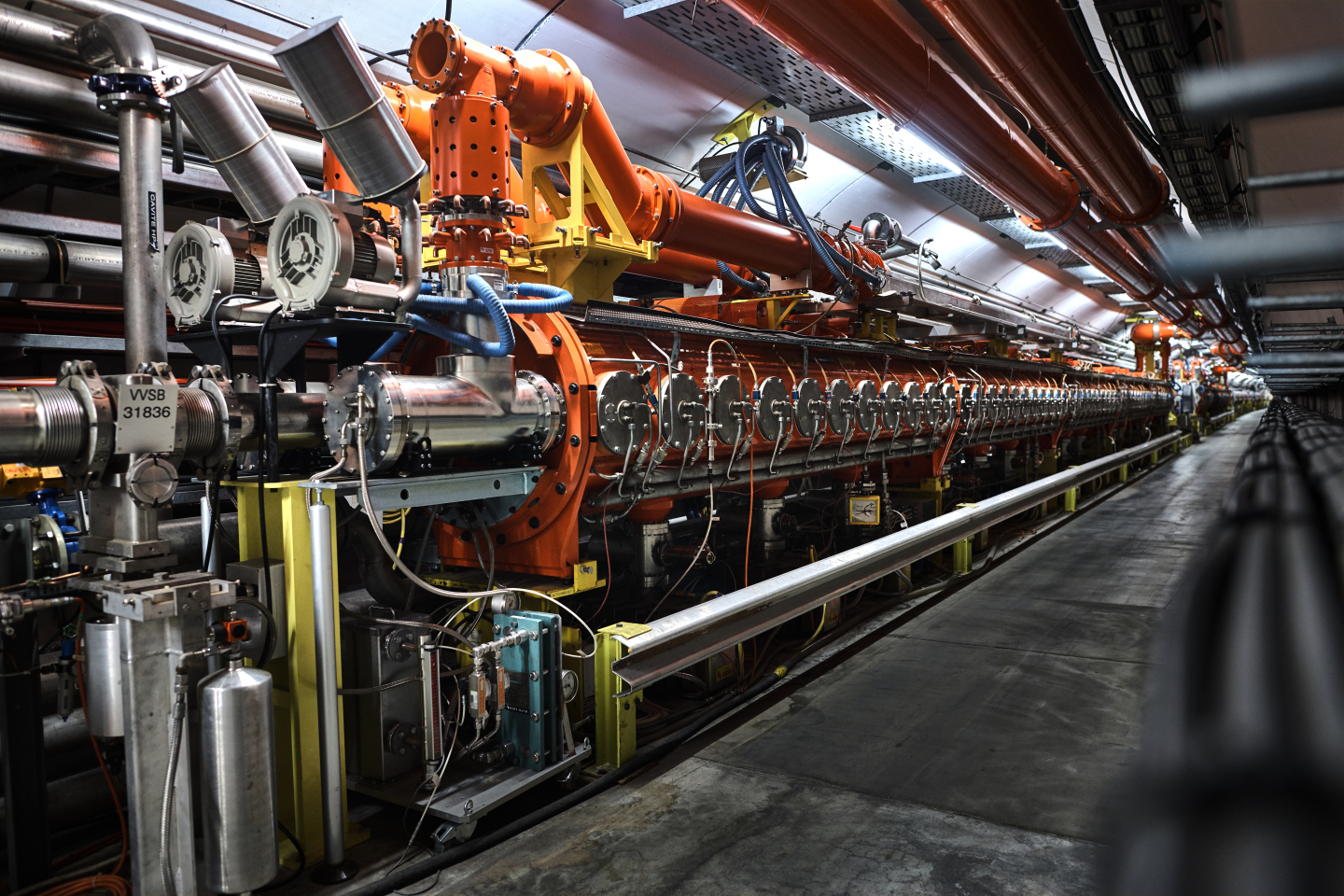

The Evolution of RF Superconducting Cavity Tuners

From mechanical actuators to AI-driven control systems, explore the technological transformation shaping the future of particle acceleration.

Executive Summary

RF superconducting cavity tuners have undergone a remarkable transformation, evolving from simple mechanical systems to sophisticated, AI-enhanced control architectures. This evolution addresses the increasingly demanding requirements of modern particle accelerators for precision, stability, and operational efficiency.

Hardware Innovation

Transition from mechanical actuators to non-contact ferroelectric tuners with microsecond response times

AI Integration

Machine learning algorithms achieving 10 Hz frequency stability through adaptive control systems

Material Science

Nb₃Sn and advanced superconductors enabling higher temperature operation and enhanced performance

Key Performance Metrics

- Traditional Mechanical Tuners: ±1-2 MHz range, seconds response time

- Piezoelectric Fast Tuners: ±50 kHz range, millisecond response

- Ferroelectric Tuners: Microsecond response, non-contact operation

- AI-Controlled Systems: 10 Hz stability, adaptive compensation

Hardware Development and Current Status

Tuner Mechanisms

Traditional Systems

Slow Tuners

Stepper motor-driven mechanical systems for coarse frequency adjustments

Fast Tuners

Piezoelectric (PZT) and magnetostrictive actuators for dynamic compensation

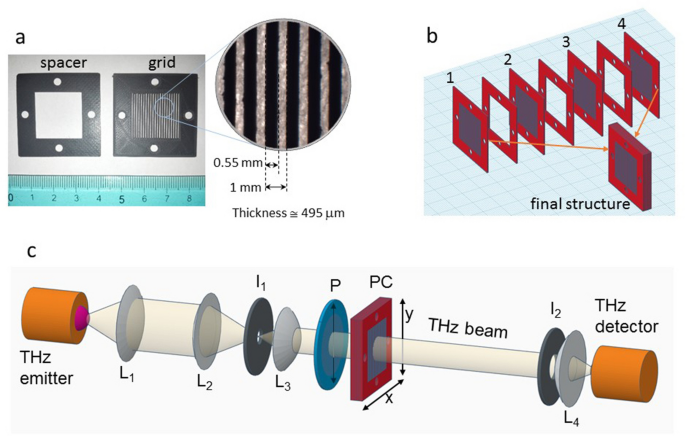

Emerging Technologies

Cavity Tuners

Non-contact electromagnetic coupling with auxiliary resonant structures

Ferroelectric FRTs

Ultra-fast electronic tuning using dielectric constant modulation

Materials Evolution

Tuner Construction

- • High-strength stainless steels

- • Titanium alloys

- • Specialized PZT ceramics

- • Terfenol-D magnetostrictive

- • Barium strontium titanate (BST)

Cavity Materials

- • High-purity niobium (Nb)

- • Large-grain/single-crystal Nb

- • Niobium-tin (Nb₃Sn) coatings

- • Magnesium diboride (MgB₂)

- • High-temperature superconductors

Material Properties

Traditional workhorse

Higher temperature operation

Liquid nitrogen compatible

Software and Control Algorithms

Control Algorithm Evolution

Traditional Approaches

PID Controllers

Proportional-Integral-Derivative control for basic feedback stabilization

Feedforward Control

Proactive disturbance compensation using measured inputs

NANC techniques for microphonics reduction

AI-Enhanced Systems

Gaussian Processes

Bayesian modeling for predictive control with uncertainty quantification

Deep Neural Networks

Complex pattern recognition and direct inverse control mapping

Feedback System Architecture

Sensing Components

- • Phase detectors

- • RF mixers

- • Analog-to-digital converters

- • Frequency discriminators

Processing Units

- • Digital Signal Processors

- • Field-Programmable Gate Arrays

- • Microprocessors

- • High-Performance Computing

Actuation Systems

- • Digital-to-analog converters

- • High-voltage amplifiers

- • Piezoelectric drivers

- • Electromagnetic actuators

Key Challenges in Control Systems

Mechanical Eigenmodes

Structural resonances can cause instability and require careful loop shaping with notch filters

Time Delay Effects

Signal processing delays limit achievable bandwidth and require advanced compensation techniques

Future Trends and Emerging Technologies

AI in Control Systems

Adaptive Tuning Algorithms

Dynamic optimization of control parameters using real-time sensor data and learned system behavior patterns.

Predictive Maintenance

AI algorithms trained on historical data to identify fault precursors and enable proactive interventions.

- • Quench prediction and prevention

- • Automated fault diagnosis

- • Optimized maintenance scheduling

Reinforcement Learning

Autonomous agents learning optimal control policies through system interaction and feedback.

Real-Time Optimization

Microsecond-scale control decisions for Lorentz force detuning compensation and beam stability.

New Superconducting Materials

Niobium-Tin (Nb₃Sn)

Enables 4.2 K operation with potential for higher accelerating gradients

High-Temperature SC

Potential for dramatic cryogenic system simplification

Alternative Materials

- • MgB₂: Balanced Tc and fabrication

- • Iron-based SC: Exploratory research

- • Nitrogen-doped Nb: Enhanced Q-factor

Other Emerging Technologies

Fast Non-Mechanical Tuning

Ferroelectric FRTs

Electric field control of dielectric properties for microsecond response

Advanced Manufacturing

- • Additive manufacturing (3D printing) of RF components

- • Integrated tuner-cavity designs

- • Customized geometries for optimized performance

- • Reduced part counts and assembly complexity

Surface Treatment Technologies

- • Ultra-smooth surface finishing techniques

- • Specialized coatings for secondary electron suppression

- • Enhanced thermal conductivity treatments

- • Nb₃Sn coating uniformity optimization

Advanced Diagnostics

High-Speed Data Acquisition

Real-time cavity detuning computation from RF power probes

Pulse-to-Pulse Correction

Intra-pulse detuning control beyond simple feedforward

Conclusions and Outlook

The evolution of RF superconducting cavity tuners represents a convergence of advanced materials science, precision engineering, and artificial intelligence. This technological transformation is enabling unprecedented levels of control and stability in particle accelerator systems.

Key Achievements

- • Transition from mechanical to non-contact tuning

- • AI-driven adaptive control systems

- • Ferroelectric tuners with microsecond response

- • Nb₃Sn material development for higher temperature operation

- • Integrated hardware-software control architectures

Future Directions

- • Widespread AI integration in control systems

- • Commercial adoption of high-temperature superconductors

- • Additive manufacturing of complex RF components

- • Autonomous operation and predictive maintenance

- • Quantum-inspired control algorithms

The Path Forward

As we look toward the next generation of particle accelerators, the continued integration of advanced materials, AI-driven control systems, and novel tuning mechanisms will be essential for achieving the performance goals of future high-energy physics experiments. The convergence of these technologies promises to deliver more compact, efficient, and cost-effective accelerator systems that will drive scientific discovery for decades to come.